The SCADA – or “supervisory control and data acquisition” – system is a combination of hardware and software that is networked to enable the capture of data within industrial processes, and the automation of those processes. The SCADA system connects sensors that monitor equipment like PLCs, motors, pumps, and valves to an onsite or remote server, and from there, graphical interfaces allow for high-level supervision of these machines and processes.

This enables industrial organizations to:

- Control industrial processes locally or at remote locations;

- Monitor, gather, and process real-time data;

- Directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software; and

- Record events into a log file.

This further enables companies to maintain efficient production, help minimize downtime, and make smarter operations decisions.

If you are looking for a cost-effective way to teach the principles of SCADA using an HMI panel, our PETRA II twin-plant trainer is the perfect solution.

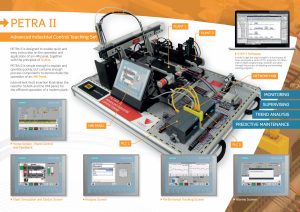

PETRA II – Advanced Industrial Control Teaching Set

The LJ Create PETRA II is designed to enable quick and easy instruction on the operation and application of an HMI panel, together with the principles of SCADA. PETRA II is simple enough to explain and operate quickly, but contains enough process components to demonstrate the operation of an HMI Panel. Intermittent fault insertion illustrates the need for SCADA and the HMI panel, for the efficient operation of a modern Industry 4.0 plant.

Check out the complete product page with a video of the PETRA II, the product information sheet, and a PDF flyer with more details.

Read more or share this PDF about the PETRA II curriculum topics, complete with screenshots from the HMI panel, and more.