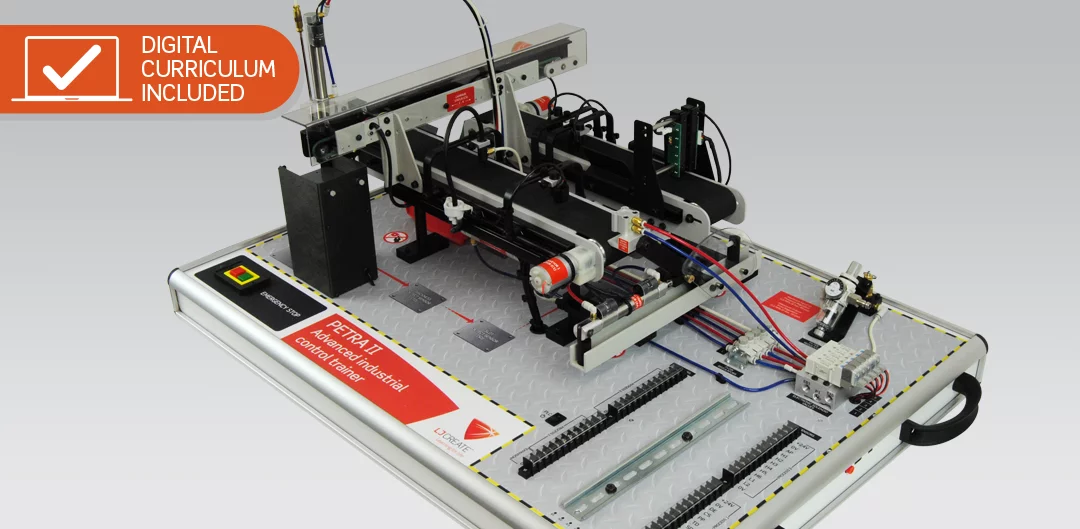

PETRA II Advanced Industrial Control Trainer

Once students have learned to program and troubleshoot a single controller and plant, the next step is to link multiple units together and monitor the performance and operation of a more complex system. This is the role of the PETRA II Advanced Industrial Control Trainer (292-01).

The trainer achieves this with a simulated industrial plant containing two distinct processes each controlled by its own PLC. An HMI (human-machine-interface) touch panel unit supervises the two PLCs, monitoring and displaying key information from sensors around the plant.

Using an industry-standard PLC programming software suite, each PLC must be programmed to control its own set of processes. The HMI panel must be programmed to supervise the two PLCs and display relevant plant information.

A student progressing through this program will explore the functionality of SCADA (Supervisory Control and Data Acquisition).

Students can use the PETRA II to develop and test PLC programs that:

- Move component parts along, and between, conveyor belts

- Control pneumatic actuators

- Monitor the outputs of a wide range of pneumatic and optoelectronic sensors

- Compare each part against its specification

- Reject non-conforming parts and accept parts that are within specification

PRODUCT VIDEO

Take a look at a PETRA II Advanced Industrial Control Teaching Set in action

Teaching Set consists of a PETRA II Trainer (292-01)

and a Siemens HMI Pack (292-03)

PLEASE NOTE: Other PETRA II options are available as follows:

PETRA II Advanced Industrial Control Teaching Set (292-00)

Siemens HMI Pack for PETRA II Advanced Industrial Control Trainer (292-03)

Siemens S71200 + STEP 7 PLC Pack (290-02/SI)